For all my platforms, I use a direct friction drive. This type of drive system is simple and allows for easy and fast resetting of the platform.

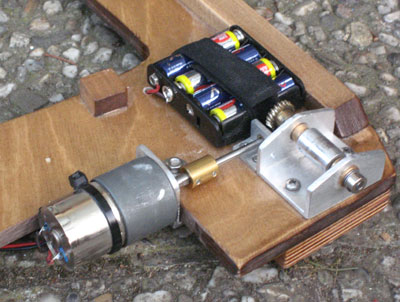

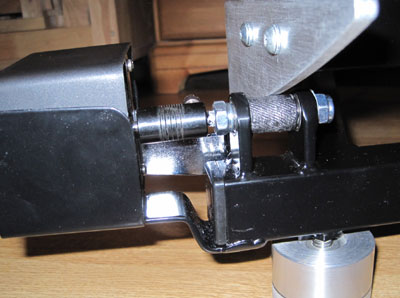

The drive system powered by an RB35 1:600 geared DC motor (Conrad electronics) and a 1:20 worm drive and a steel drive shaft driving the platform by friction. Due to weight of the Dobson and the vertical force transmission, the friction is high enough to prevent slipping. The relatively thin drive shaft (5mm) causes in the long term some wear on the segment surface. It is therefore better to use a somewhat thicker shaft.

The motor speed is controlled by the motor voltage, which can be achieved by an adjustable resistor (most simple solution, as for my 14"er) or by a voltage control unit. Both solutions give satisfying results, but the voltage control unit has the advantage that the motor voltage does not need to be re-adjusted as the batteries get weaker.